Phase 1 - Research

Research Solutions

Idea’s industrial design research; identifies the aesthetics; ergonomics; user experience (UX); demographic; patent (IP) and marketing needs of a product and design brief.

Phase 1’s outcome validates and confirms the project/product brief and defines the structure of the project.

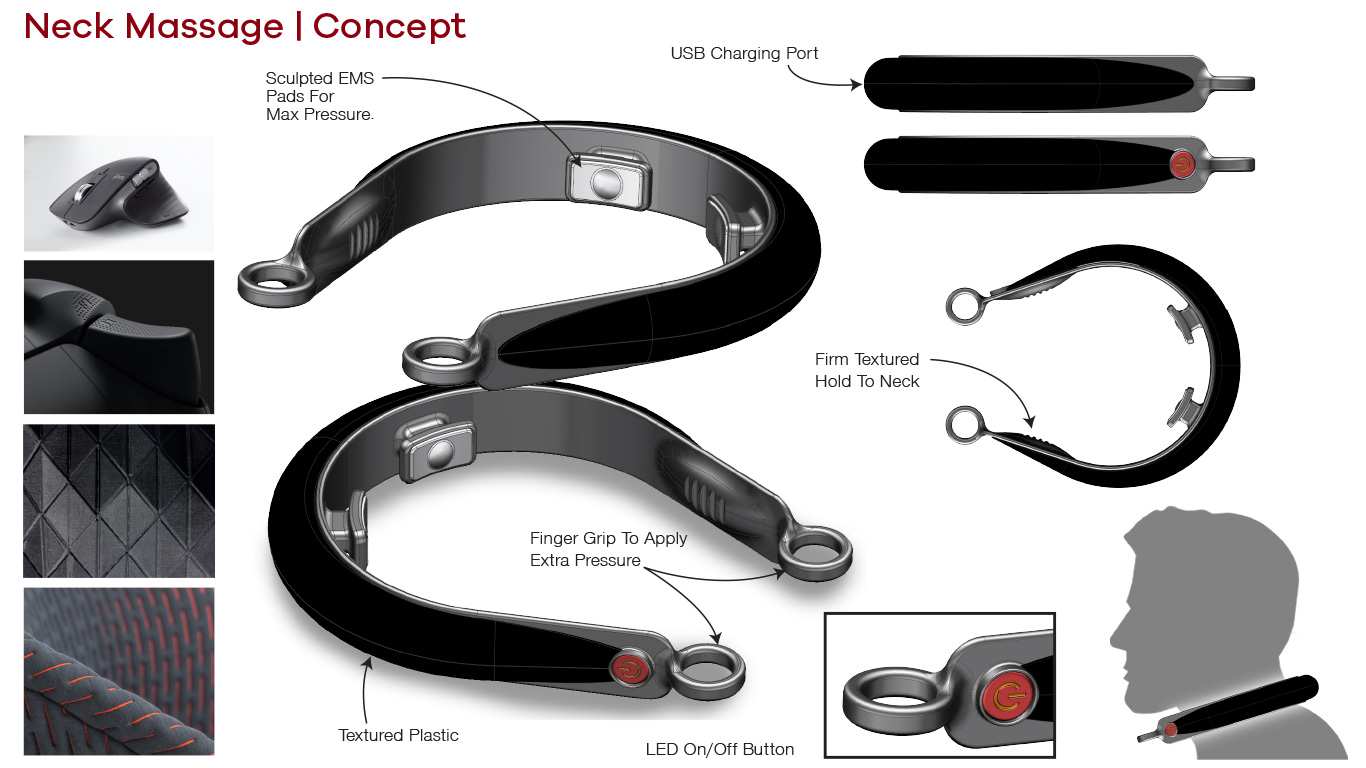

Phase 2 - Concept

Concept Solutions

Idea’s concept sketch process evolves the product brief into an early visual presentation showcasing aesthetic styling direction; product features; and engineering intent.

Phase 2’s outcome validates and sets the design direction and showcases the product at the early stage.

Phase 3 - Form Study & Mock-Up

Mock-Up Solutions

Idea’s designers 'hand crafted' form study models to further assist aesthetic and ergonomic resolve of visually demanding products, literally bringing concepts to life.

Idea’s mock-up model build techniques provide an early insight to product performance, size/ proportion, and weight/ balance; which are important factors for early proof of concept.

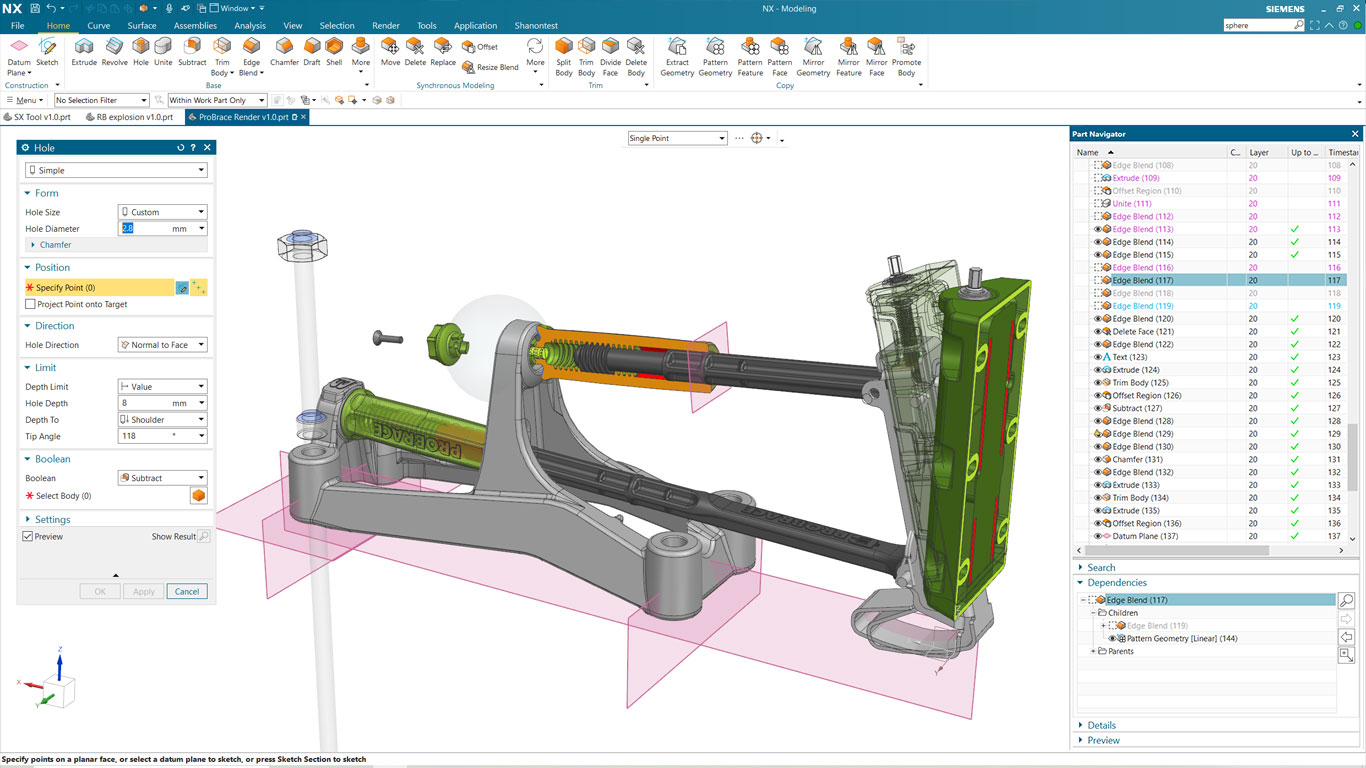

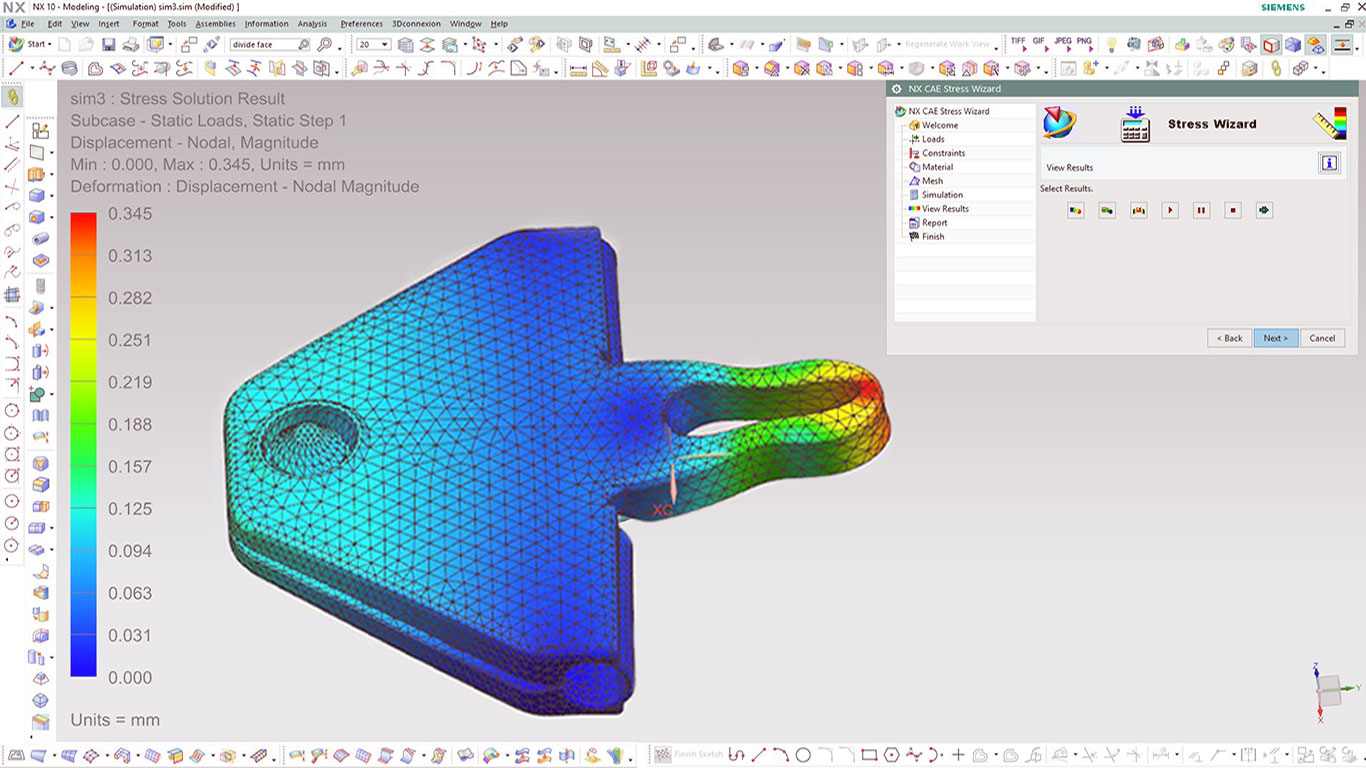

Phase 4 - Engineering

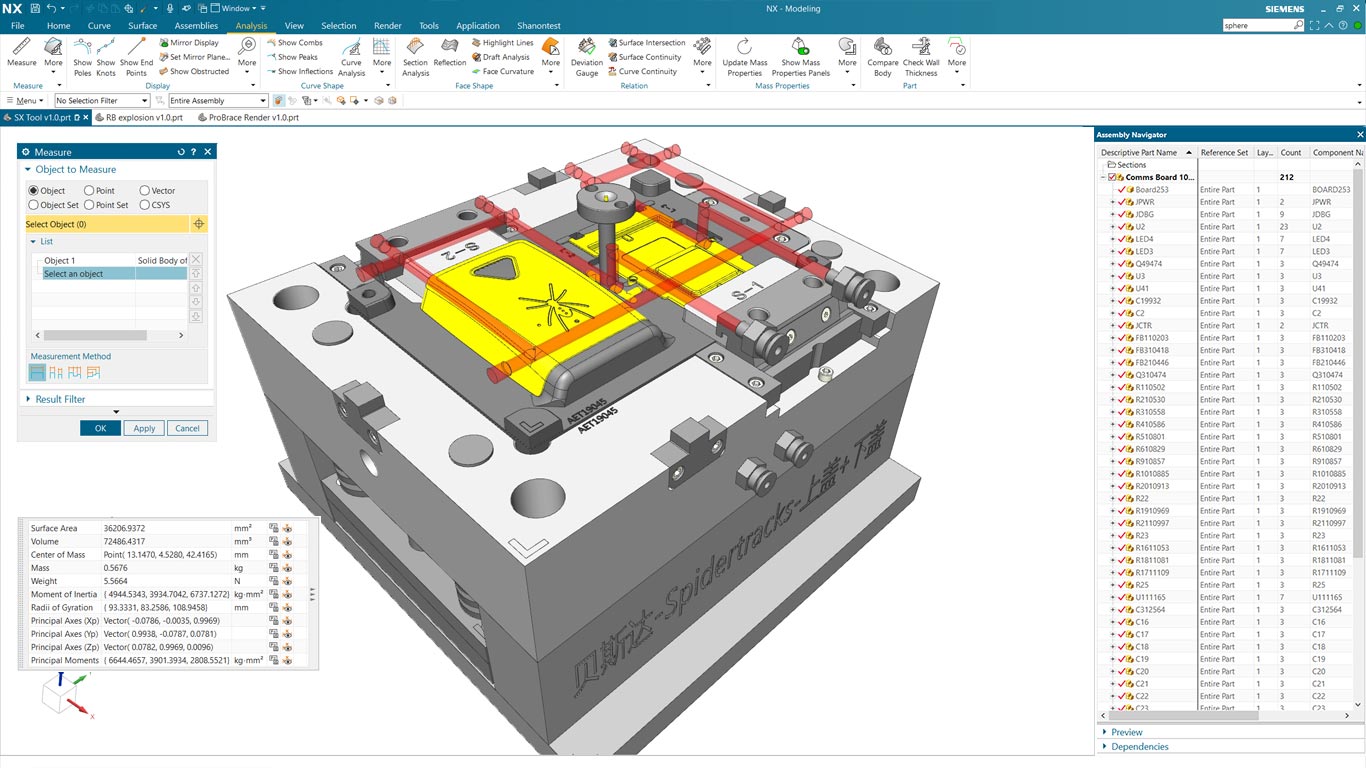

Engineering Solutions

Idea’s design engineers work with the very latest in 3D CAD modelling and simulation software; NX by Siemens, capturing complex surfaces, optimising components for strength, weight, and performance- allowing for alternative material selection.

Integrated PCB design; software programming; and app design is captured within a 3D working product assembly.

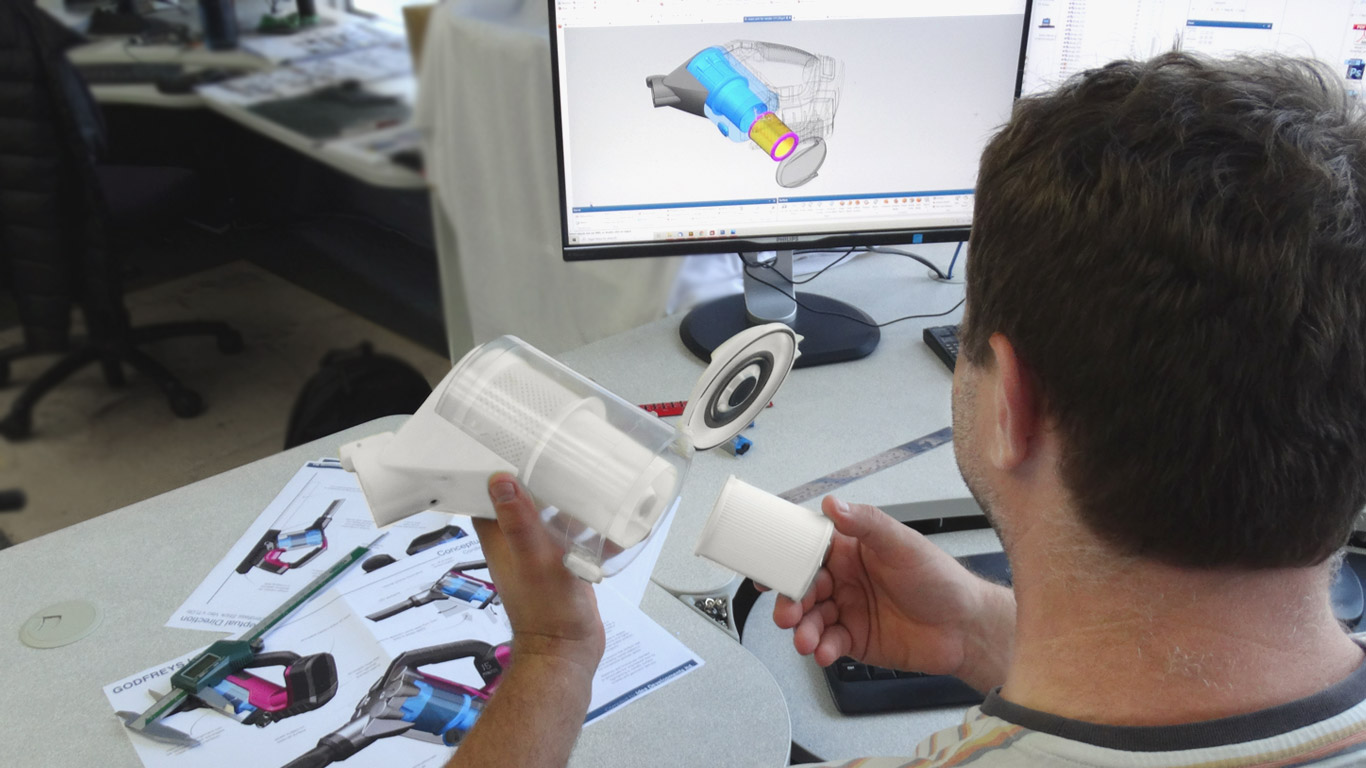

Phase 5 - Prototype

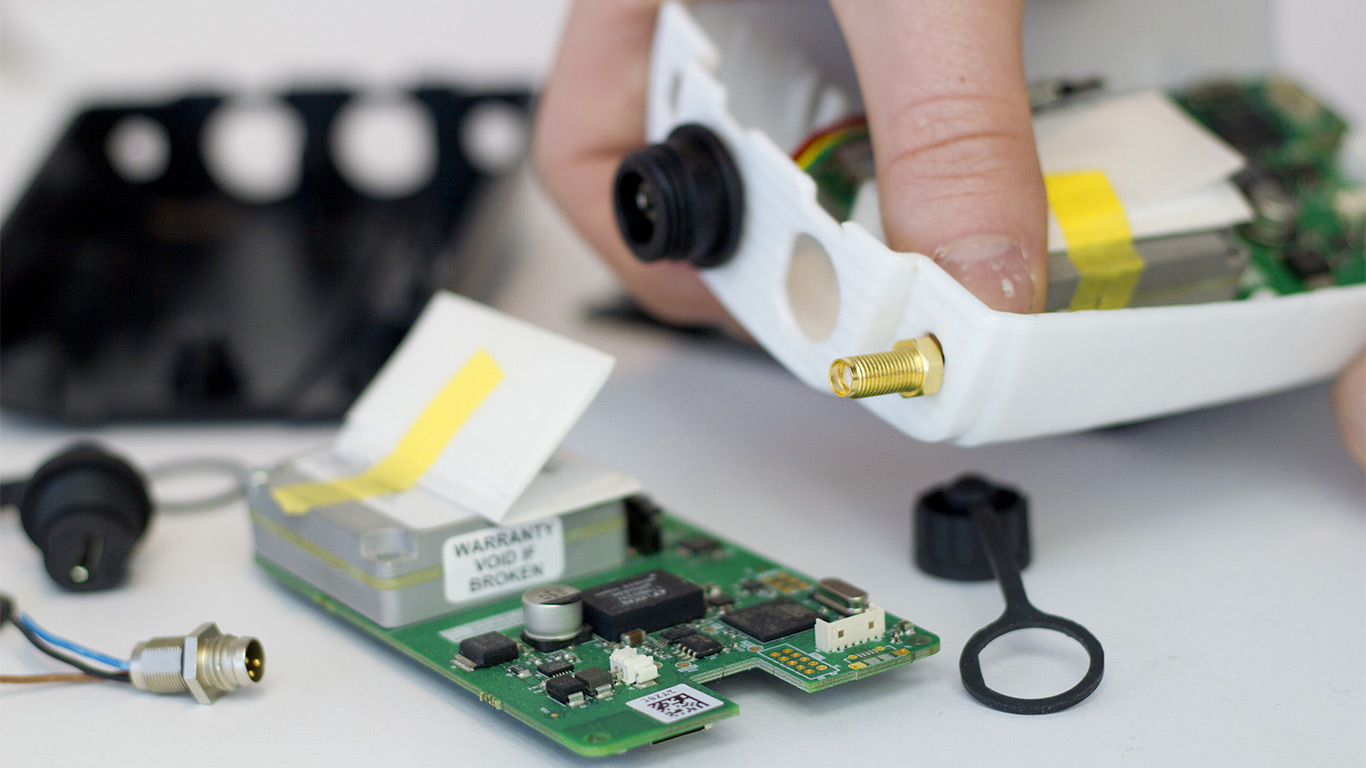

Prototype & Short Run Solutions

Idea specialises in producing prototypes from a variety of prototype build methods, and production-quality materials and appearance; validating and showcasing the product to the market before investing in production mould tools.

Phase 5’s outcome provides a marketable, working performance prototype as close as possible to the finished product.

Learn More (pdf)

Phase 6 - Specification

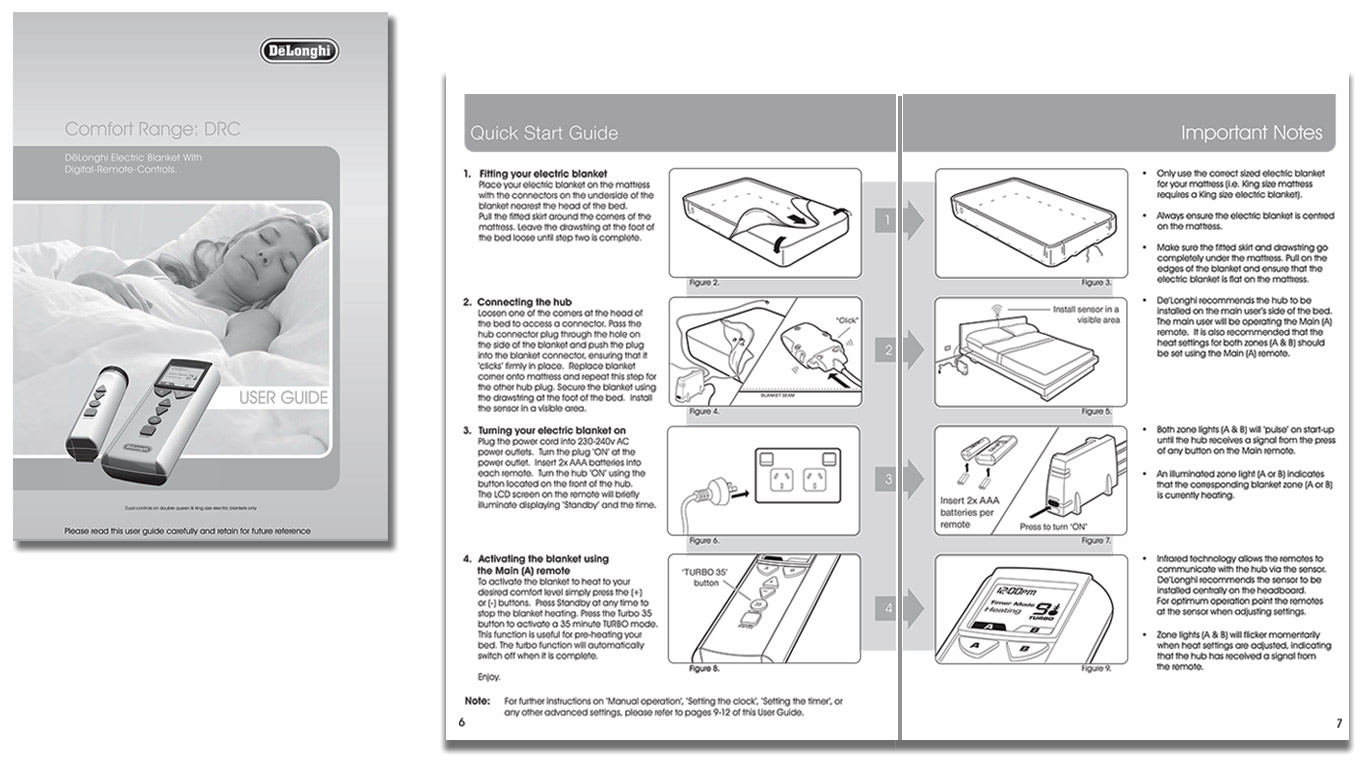

Document Solutions

Idea’s design specifications ensure critical areas of the design function and appearance are clearly communicated in product engineering drawings, patent applications, manufacturing specification kits, and instruction manuals.

The resulting product specifications from Phase 6 mitigate risk and ensure a smooth transition into manufacturing, regardless of whether it is to be manufactured with Idea’s factory or your own.

Phase 7 - Tooling

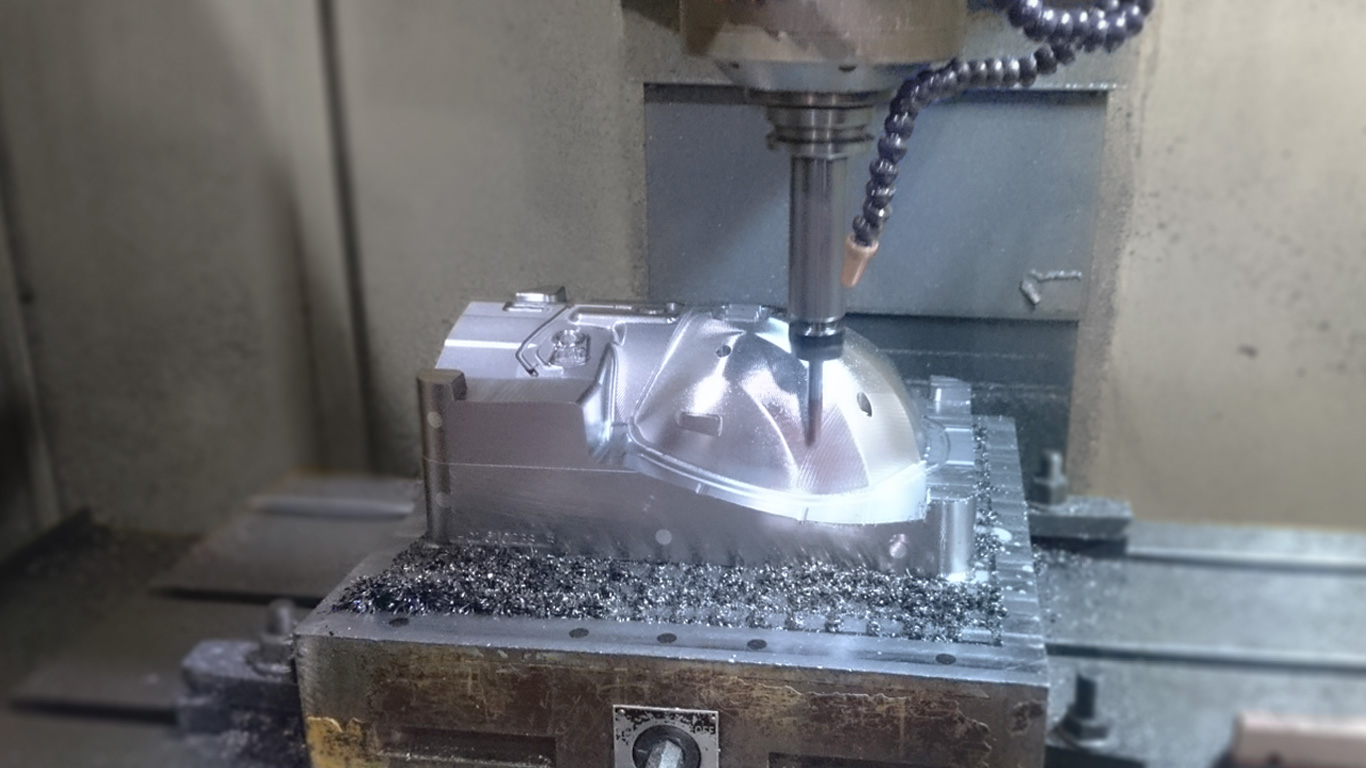

Tooling Solutions

Idea’s NZ-based design and engineering team provides tool designs with ‘off-tool’ part checks, to efficiently manage the tooling process. Our China-based team provides 'hands-on' assistance ensuring quality, efficiency, and supply to meet your requirements.

Idea has access to a multitude of different mould tooling methods and processes for the best economic investment in tooling and profitable outcome for the product.

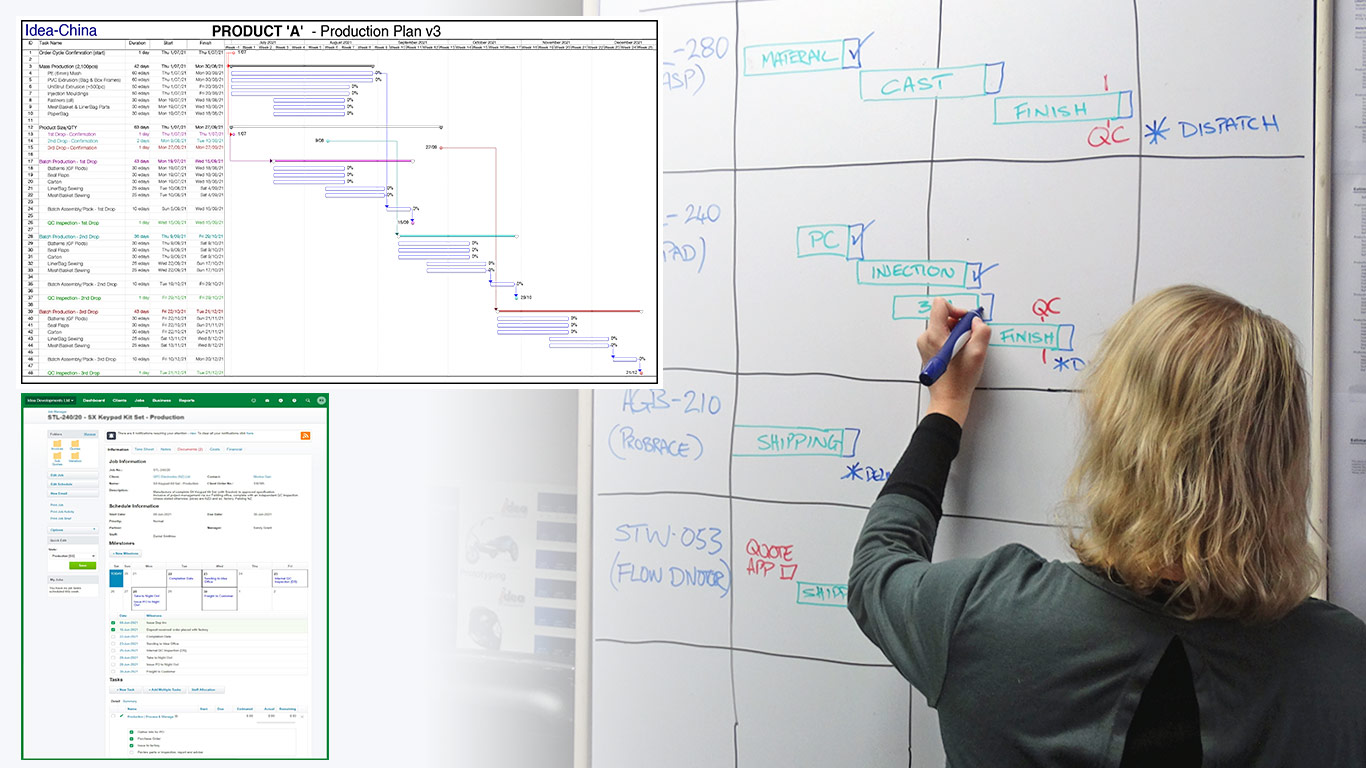

Phase 8 - Production

Production Solutions

Idea provides the complete supply solution of produced components, products, and sourced goods. Idea China's manufacturing operation has access to a multitude of specialised suppliers and provides full product assembly; sub-assembly as a kit set to meet your requirements; or individual components manufactured to order.

Idea's NZ design team understands and sets the quality control specifications for manufacture, and provides independent quality inspections before arranging shipping of finished goods.

Learn More