User Centred

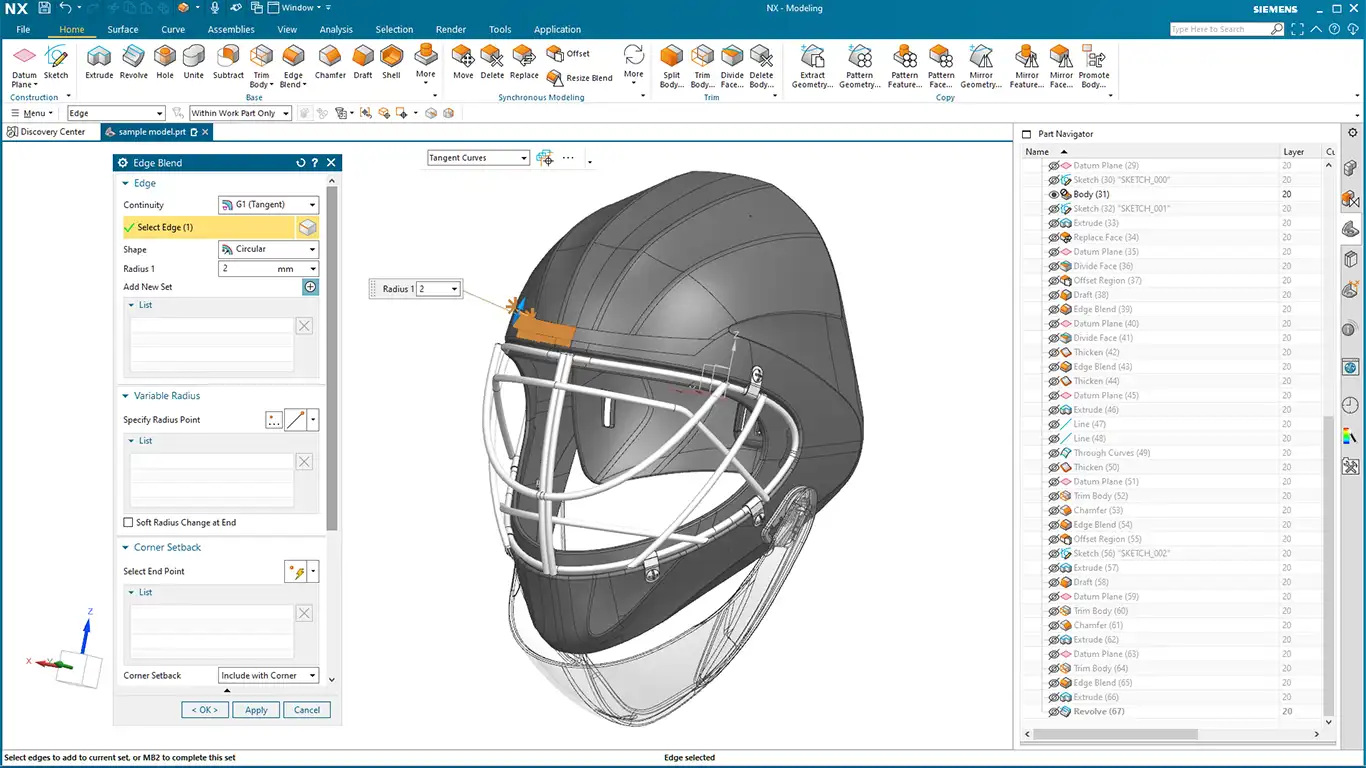

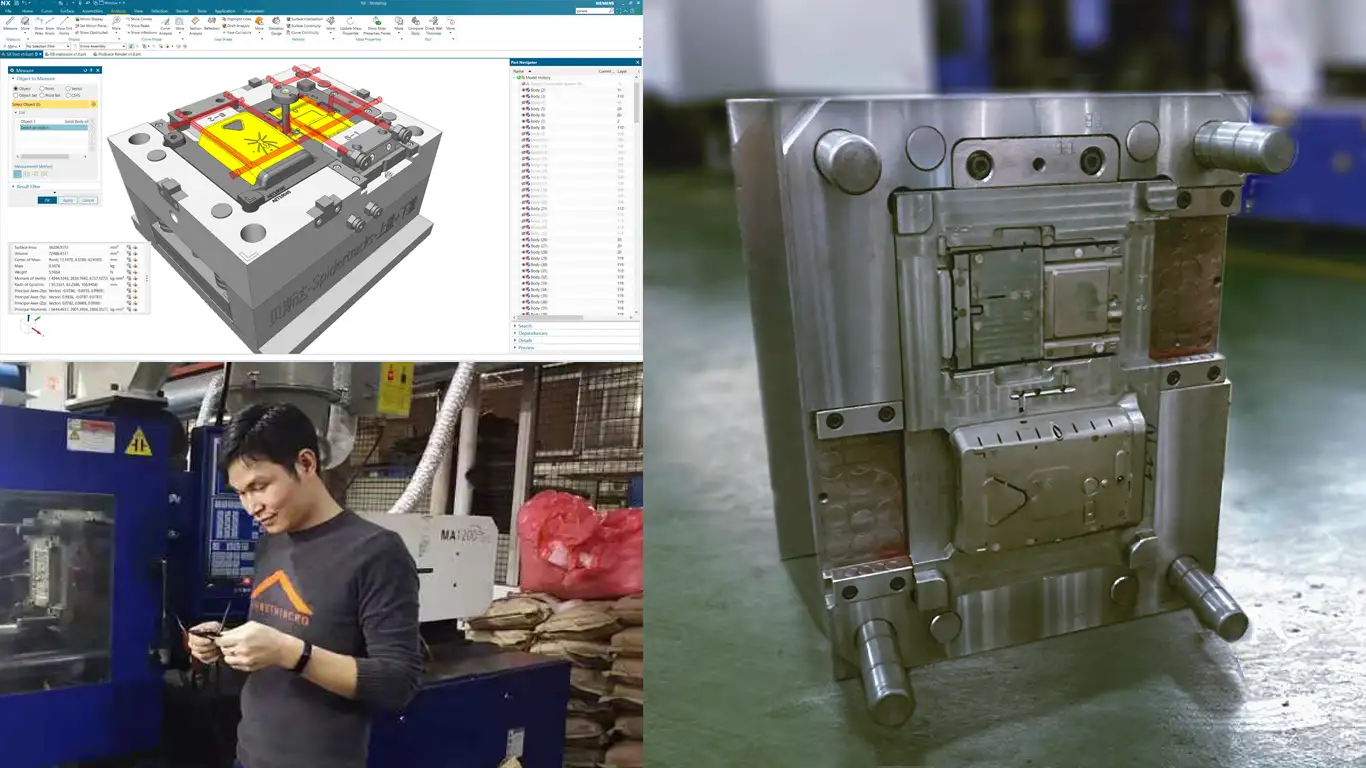

Project - OBO Carbon Helmet

OBO, a global leader in field hockey goalkeeping equipment, has long partnered with Idea Developments to design and engineer their headline helmet range.

For the next-generation model, OBO challenged Idea to integrate carbon fibre into the shell structure to improve strength and performance. The brief called for new functional features while retaining the helmet’s signature character — comfortable and organic in fit, yet visually assertive to opponents.

Extensive ball-impact testing was conducted to validate protection levels, with refinements made to meet both the aesthetic and CE safety compliance requirements. Idea carried the design through to production, developing mould tooling, defining quality-control specifications, and supporting the CE approval process to deliver a fully compliant, production-ready helmet for OBO.

Project - Solution

Consumer Appliances

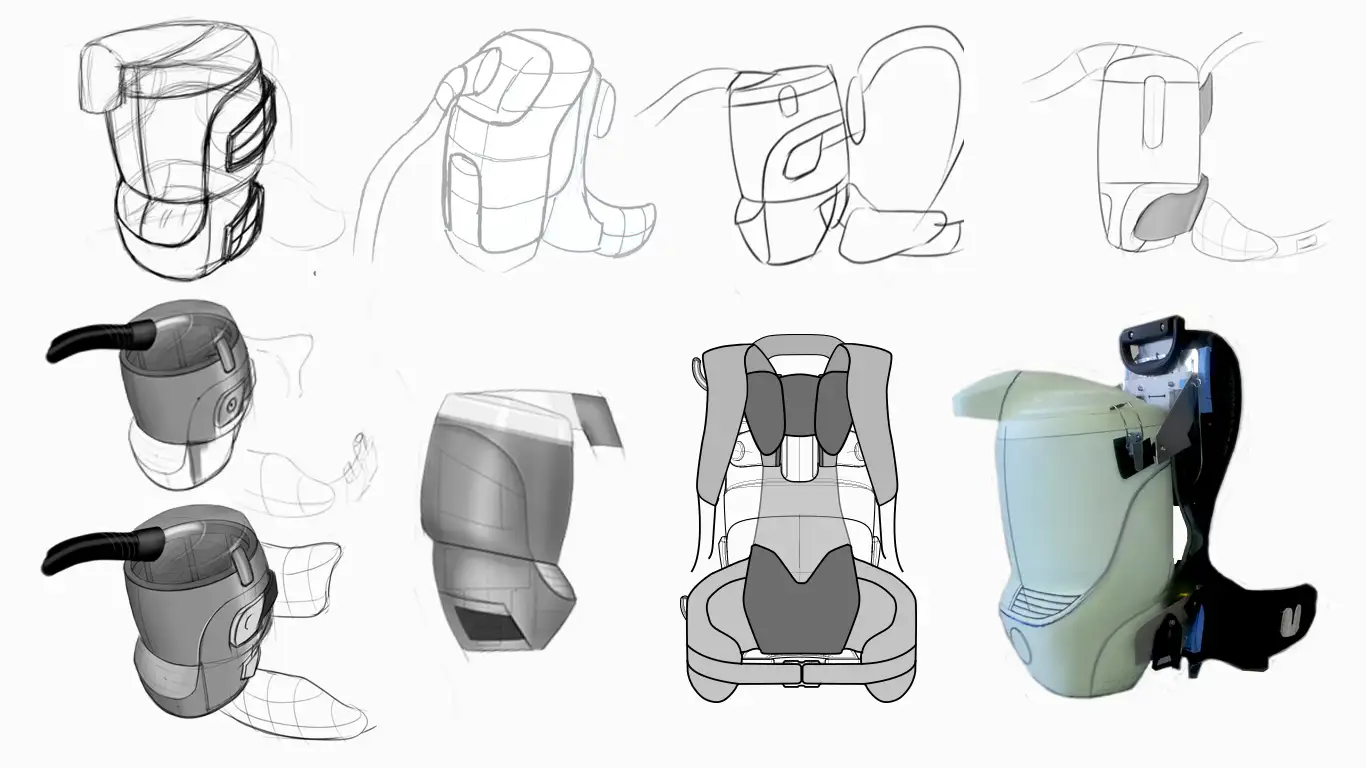

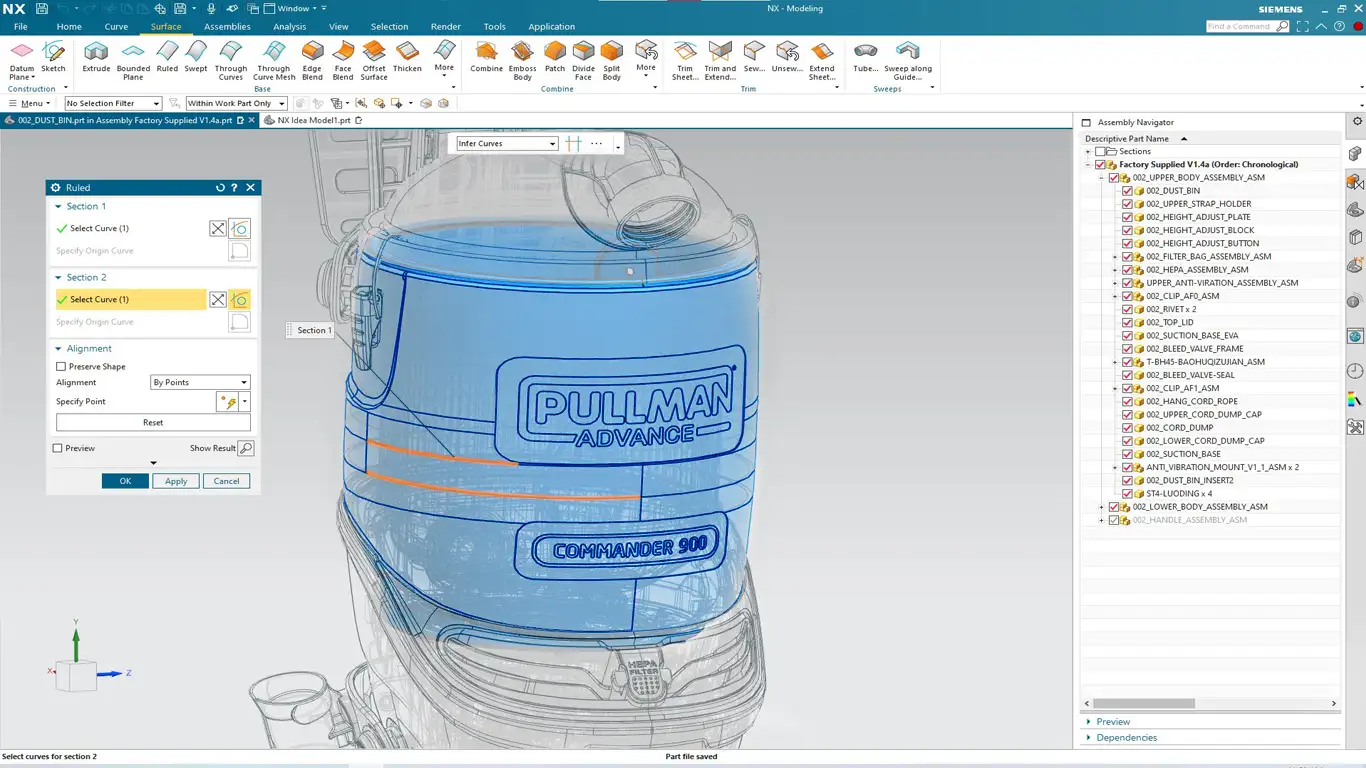

Project - Vacuum Backpack

Our client is a leading Australian Vacuum Cleaning specialist and wanted to design a higher quality option for backpack vacuum cleaners from the ground up, with a specific focus on being lightweight, comfortable, and high-performance. For this client comfort was the most important criteria.

Creating mock-ups was crucial for this project as every little piece of design placement needed to be carefully considered; the on/off switch, clips, etc. all had to be placed strategically to ensure the most comfortable experience. Idea created realistic mock-ups so the Clients could test out the feel and weight of what would be the final product. It was also very important to establish manufacturing methods during this design process; this was achieved by discussing the tooling budget and ensuring the tooling methods were included in the design to meet the budget requirements. On completion Idea produced engineering ready 3D CAD files directly to the clients manufacturing partner.

Project - Solution

Electronic Products

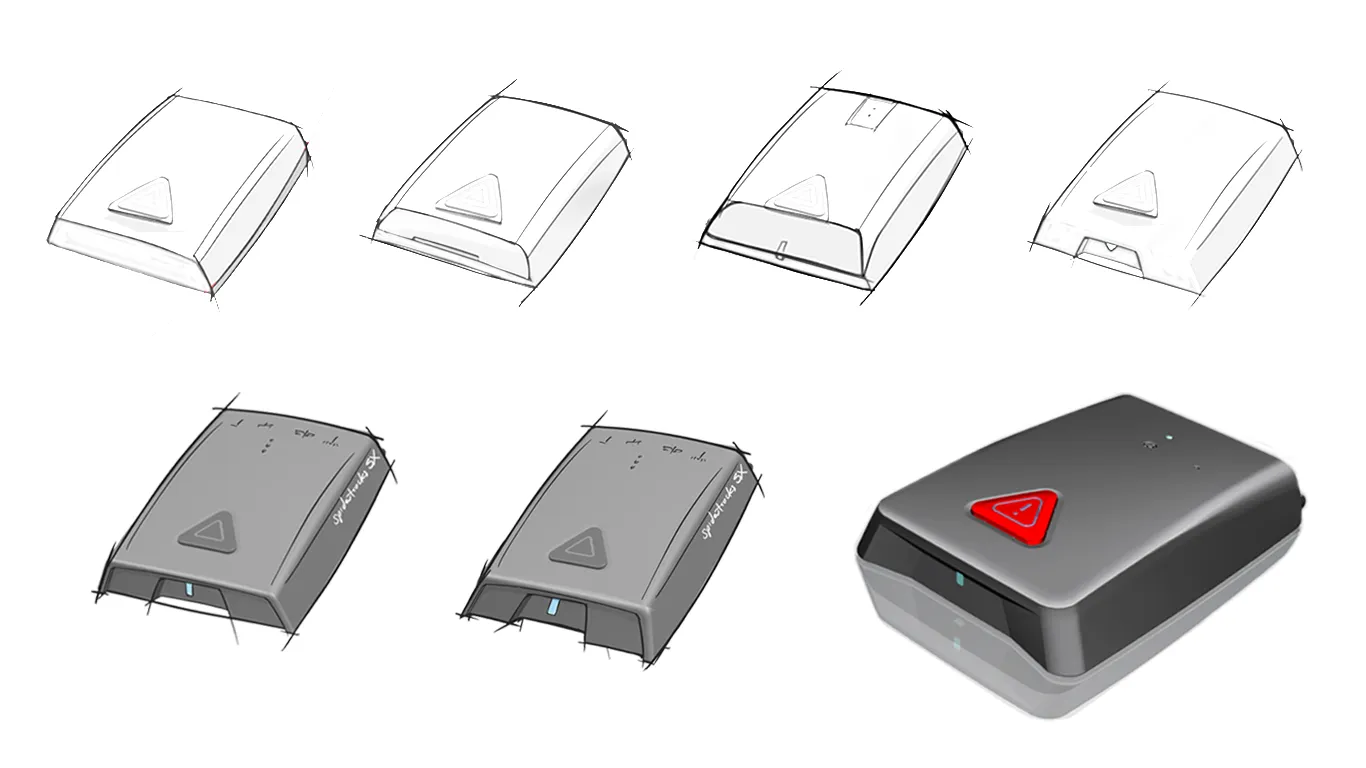

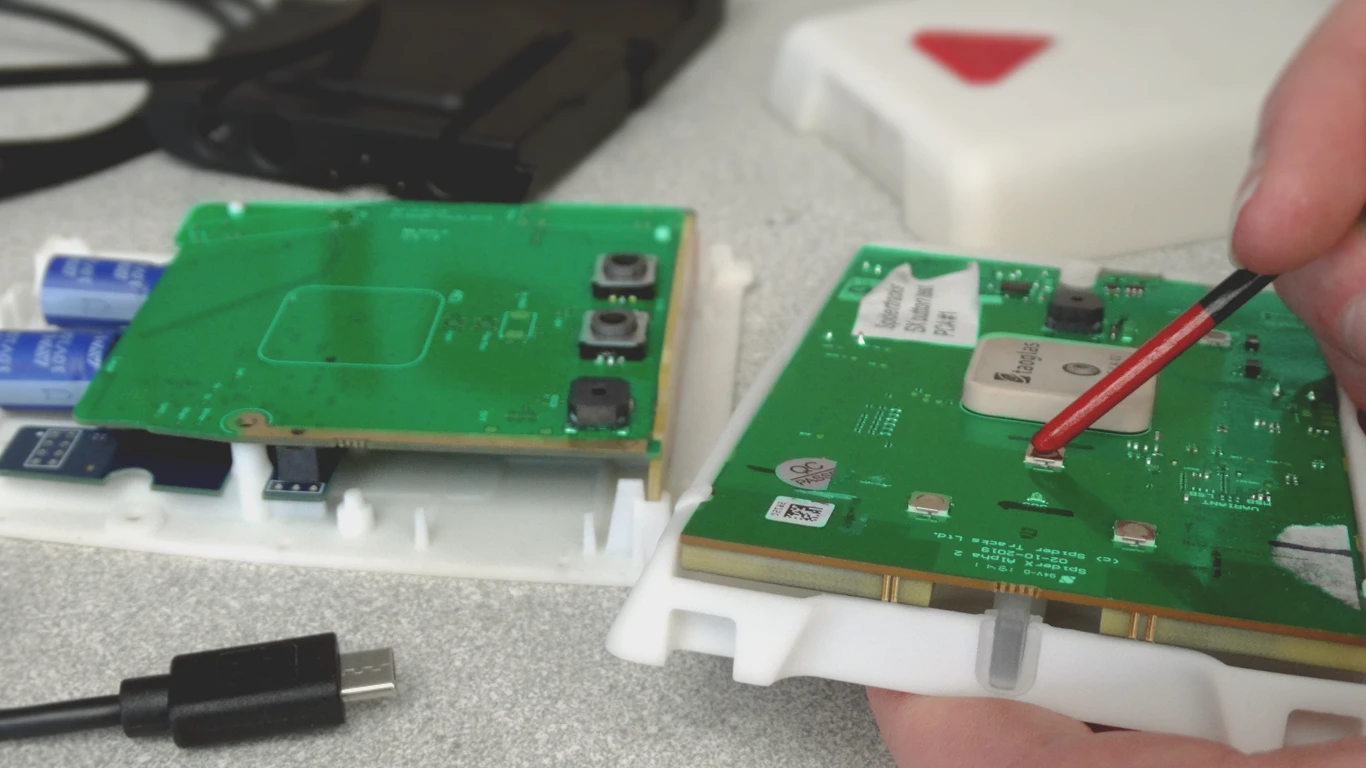

Project - Spider SX

Our client is the world leading provider of satellite-based real-time flight tracking. Their original product transformed the industry, but they approached Idea wanting to update their product that would leapfrog their previous model.

For this product user interface was the most important part; it had to be non-intrusively mounted in order to not distract the pilot while flying, and easy to access the SOS when in an emergency. It also had to be extremely strong to survive huge impact, and perform as a data transmitter and receiver to the highest capacity. To achieve all of these criteria Idea first worked on presenting the conceptual expected outcome for approval and created prototypes with close collaboration and co-development of PCBA. On completion Idea produced production tools, quality control specification with ongoing production supply (Idea-China) to the client.

Project - Solution

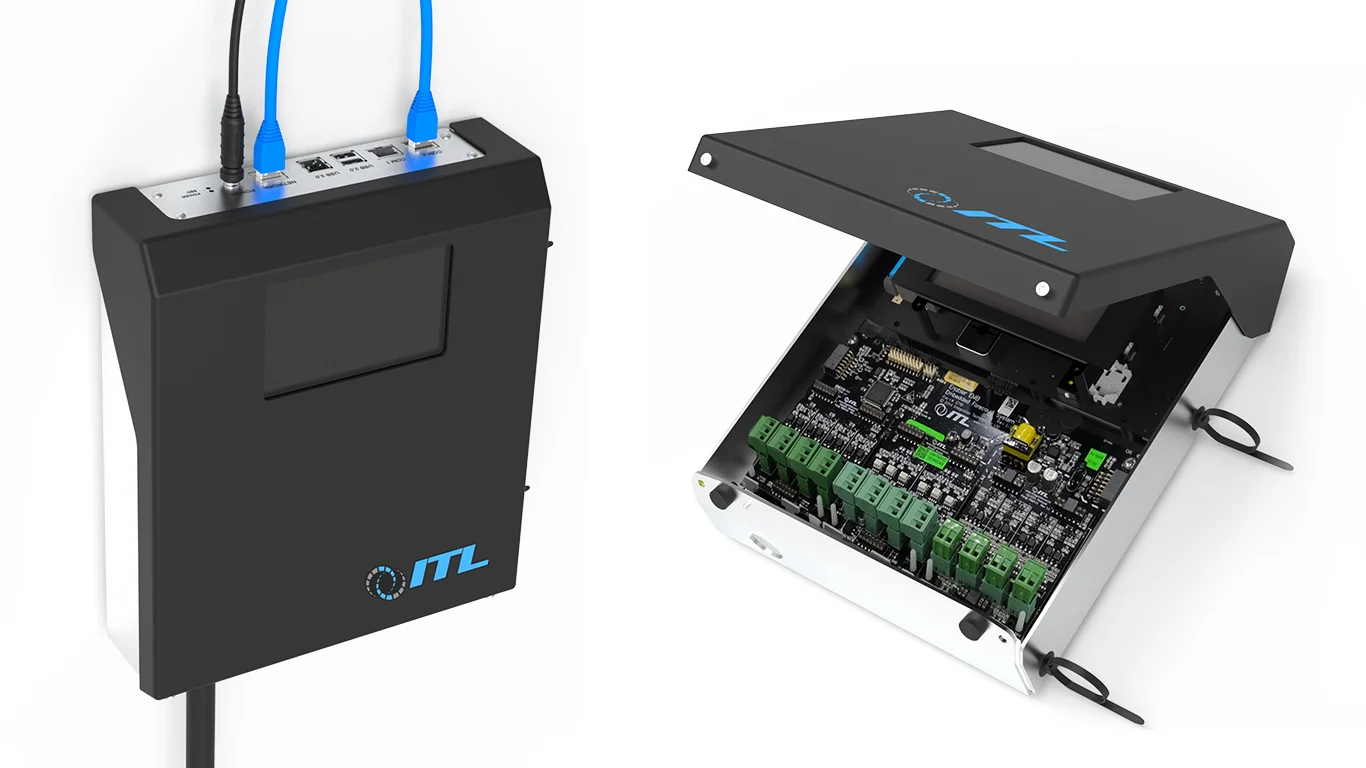

Product Engineering

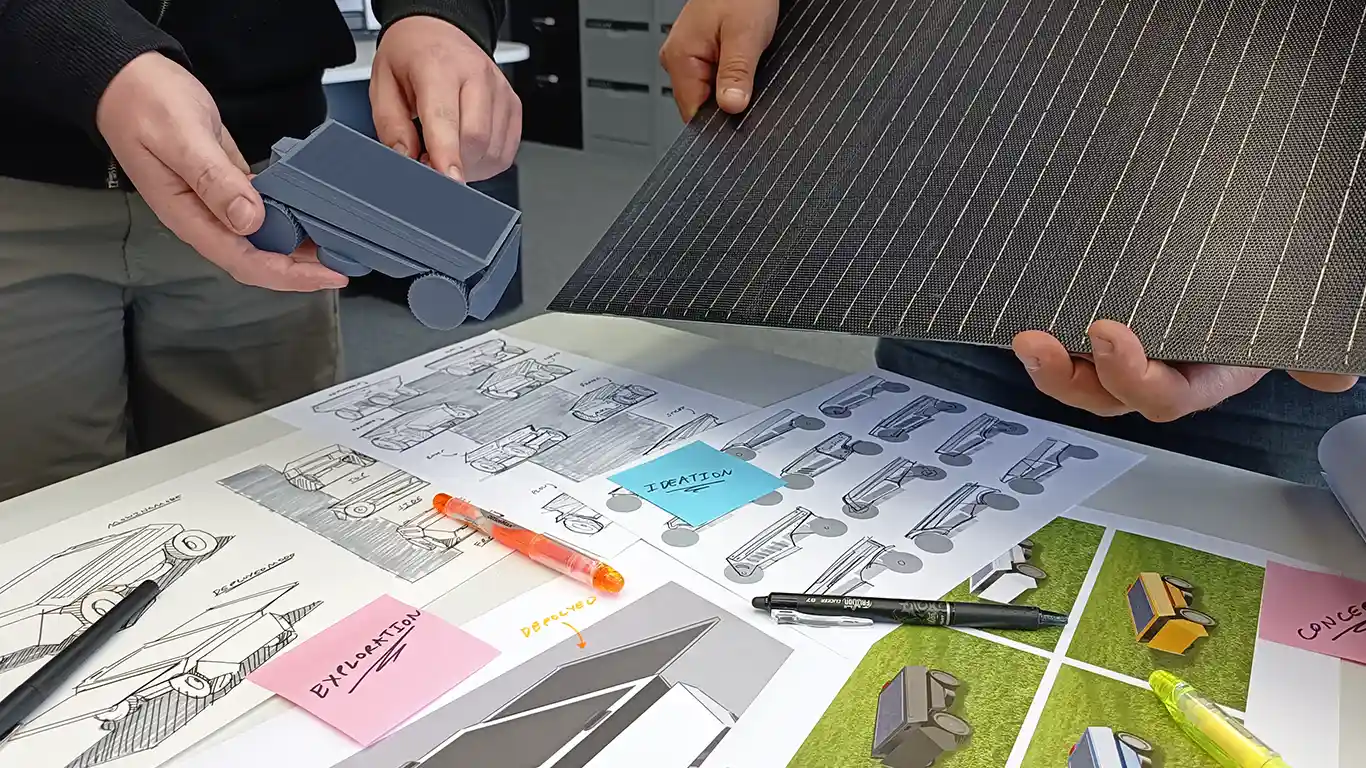

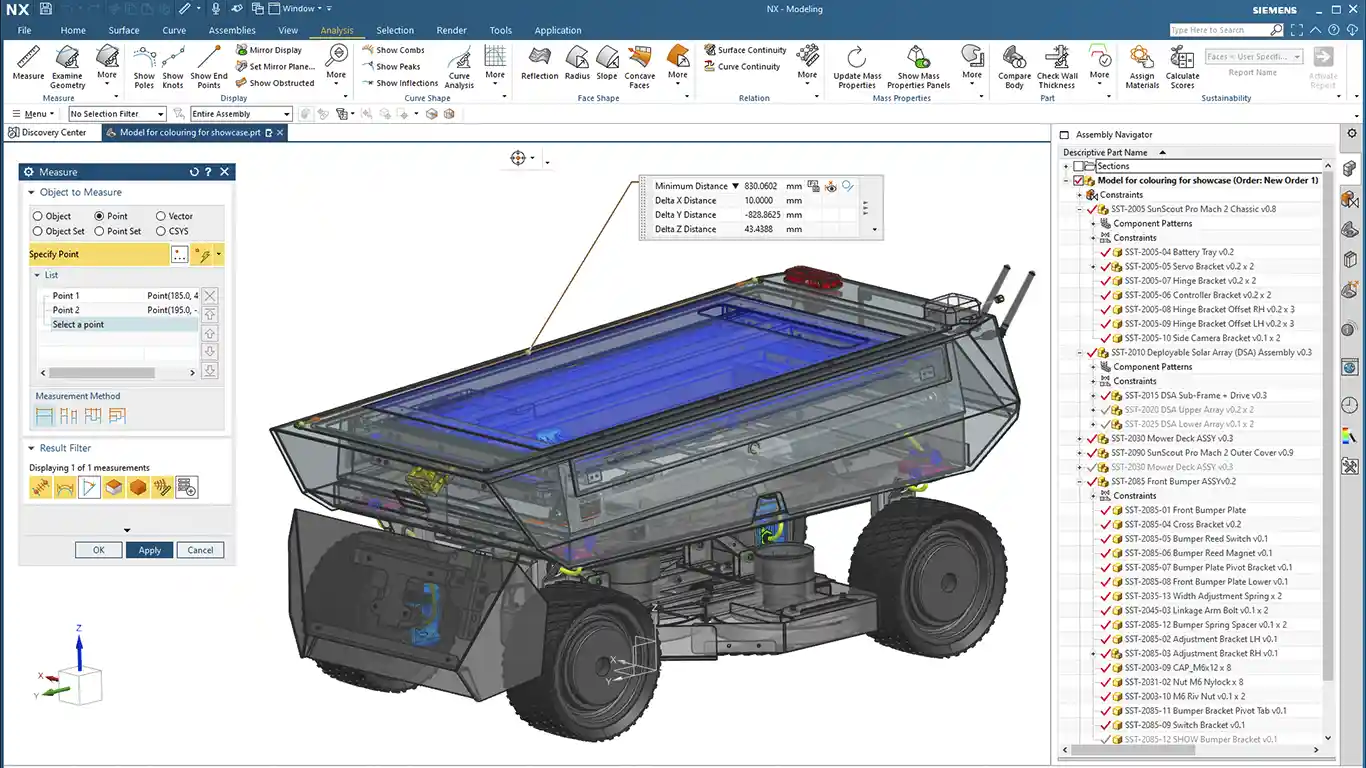

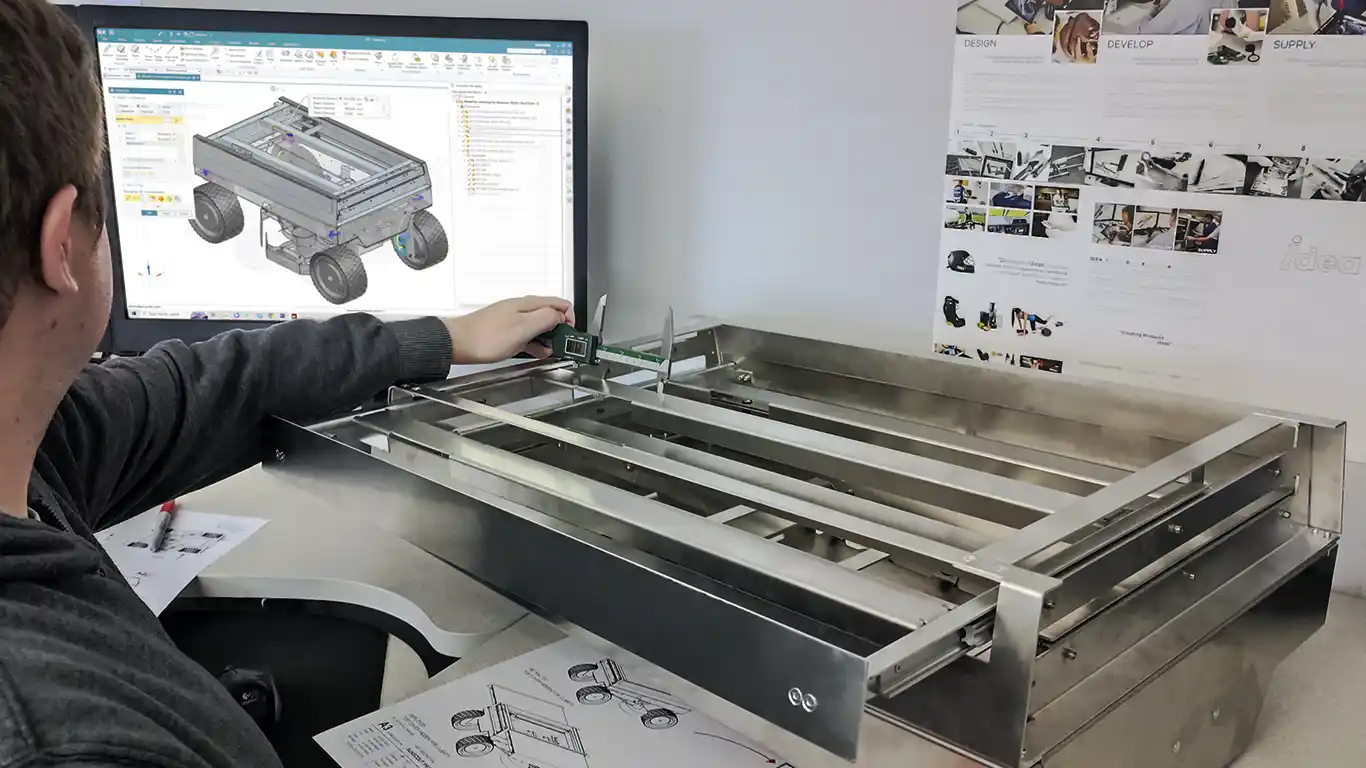

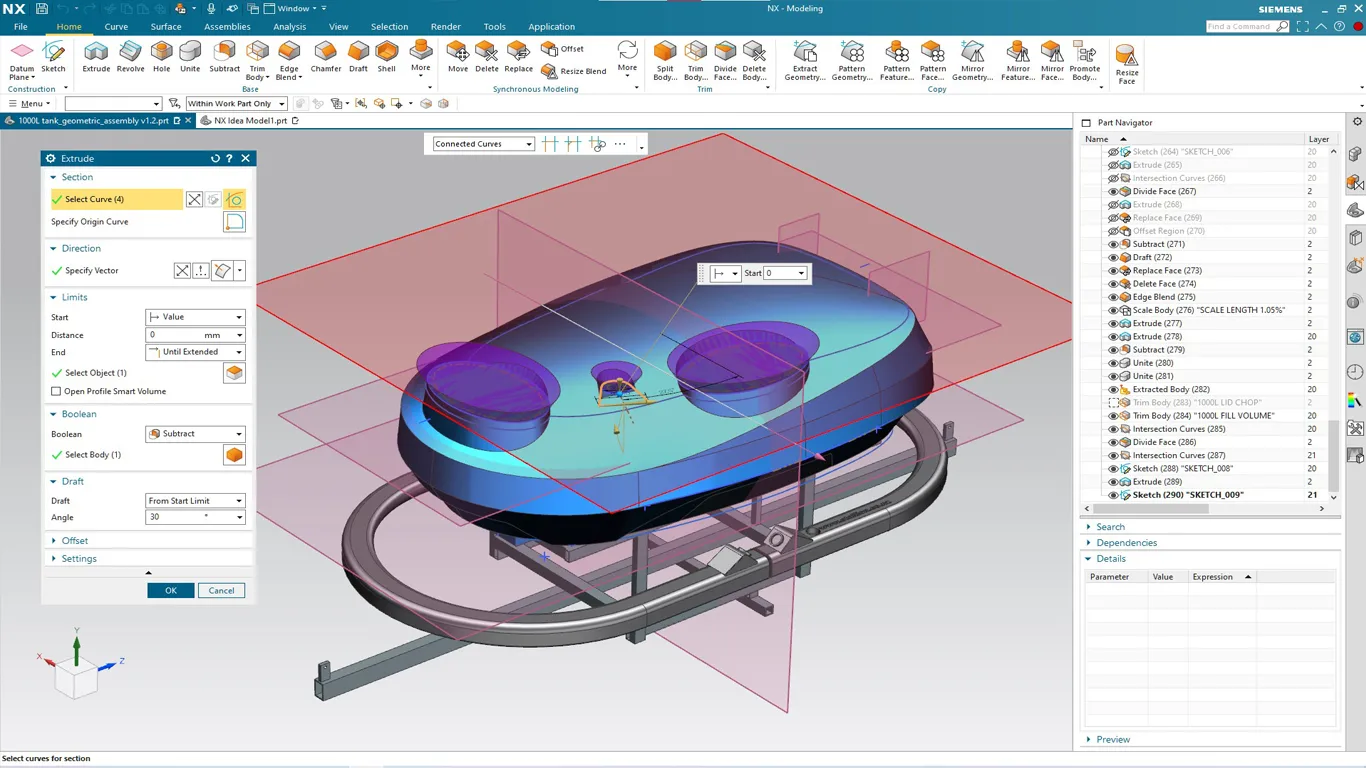

Project - SunScout Pro-Mower

Our client, a pioneering solar company called SunScout, is dedicated to eliminating fossil fuels and achieving maximum environmental sustainability across robotic systems, vehicles, and mobile machinery.

SunScout approached Idea to design and develop a new solar-powered robotic lawn mower for their product range.

Collaborating closely with the client’s suppliers and in-house manufacturing team, Idea's industrial design and engineering team followed a strategic New Product Development (NPD) program to deliver an innovative mower design.

Utilising Design for Manufacture (DFM) and Design for Assembly (DFA) techniques, our engineering design team developed detailed 3D CAD assembly models, transforming concepts into engineered products with prototype development, ready for manufacturing and global distribution of finished products.

Project - Solution

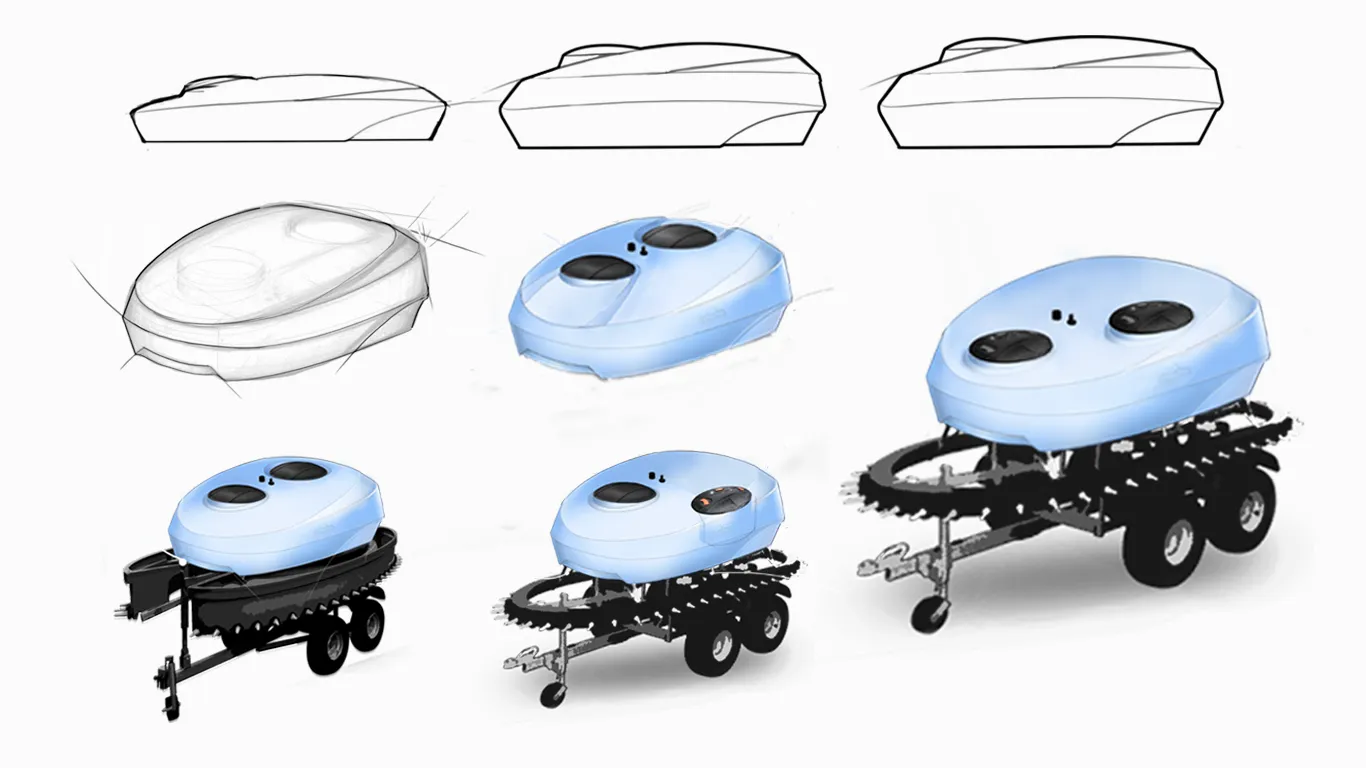

Agriculture & Horticulture

Project - Calf Feeder

Our client is an Industry Leading, well-established milk feeding products for animals. Their current product was selling well on the market but they wanted an update. They wanted the sports car equivalent of a new milk feeder range.

The way it worked and its current size did not need to change, focus was on the aesthetics because the shape and look were crucial to stand out from their competitors.

Idea created a huge full scale foam mock-up, which both served as a way to style and capture the design as a full scale object that the clients could run their hands over and understand all the changes and approve all the designs before starting 3D CAD. This also allowed the manufacturers/ mould-makers to see how to make it. On completion Idea worked directly with the client's mould maker producing required 3D CAD data and drawings.

Project - Solution

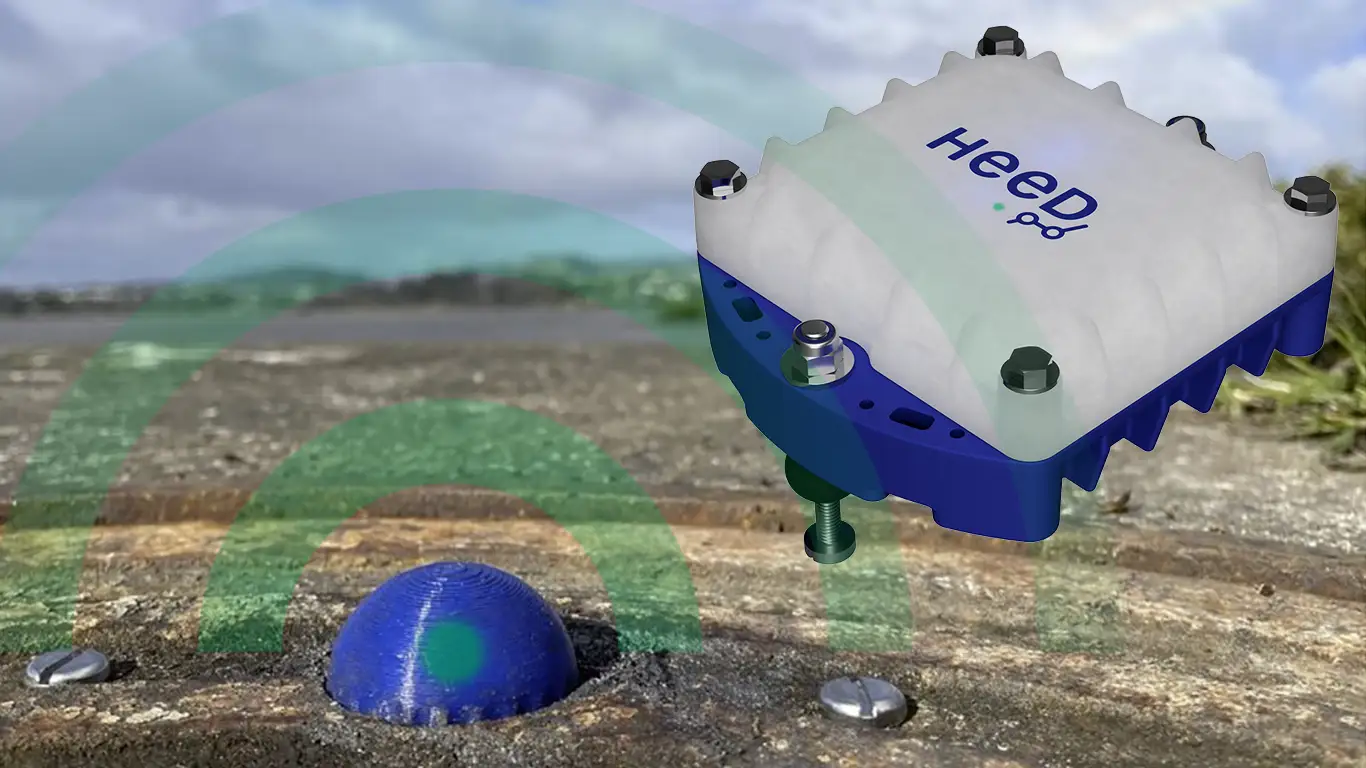

Health & Medical

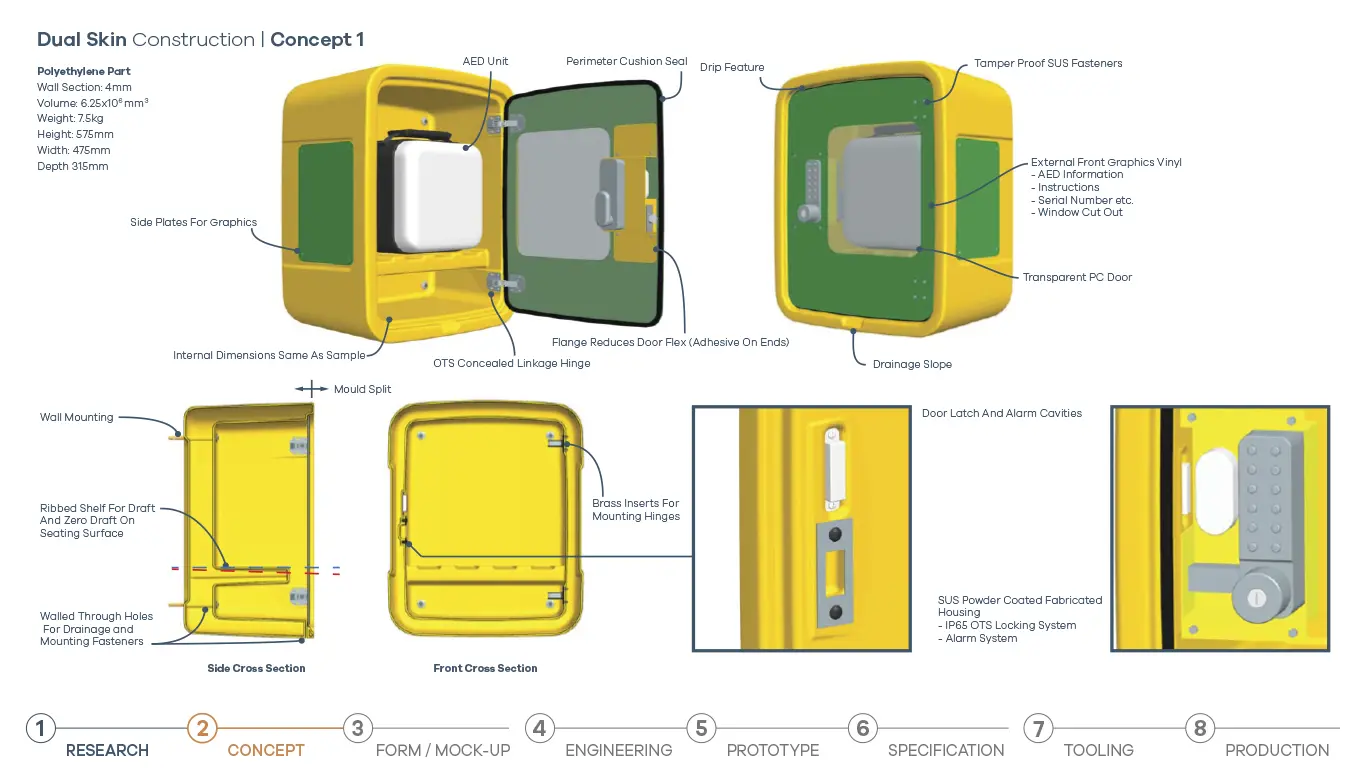

Project - AED Cabinet

When Mouldings Unlimited a plastic rotational moulding company, was approached by Wellington Free Ambulance with an opportunity to develop a new outdoor AED cabinet, they came straight to Idea Developments.

The new cabinet requirement arose due to the harsh environmental conditions of the coastal Wellington Harbour, proving too severe for standard metal constructed AED cabinets.

Before committing to production funding, a viable product concept was required – and having collaborated on numerous projects since 2009, Mouldings Unlimited turned to Idea Developments confident in their team’s expertise in research and product design from a manufacturing perspective.

Idea’s design and engineering team developed a conceptual product that met stringent weatherproofing and corrosion resistance requirements while remaining cost-effective for rotational moulding.

The solution successfully balanced ‘ease-of-use’ and standout visual appearance with functional performance and manufacturability.