Product Engineering - QuickSet Insulated Foundations

Project - QuickSet

When QuickSet Systems approached Idea, their existing insulated concrete floor foundation system was already a durable, cost-effective, and eco-friendly solution, offering thermal efficiency that exceeded New Zealand’s building code standards.

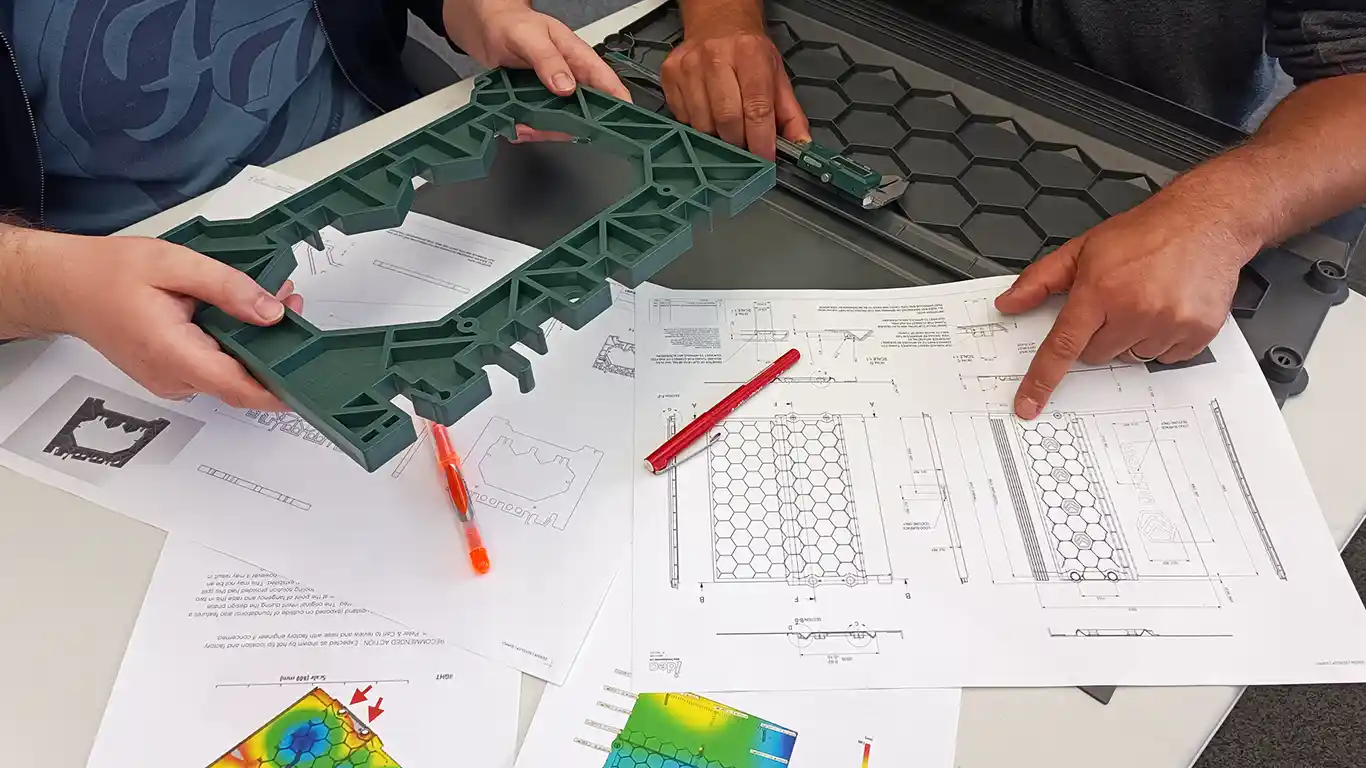

With growing demand for their product, QuickSet needed to transition to mass production, requiring changes in both materials and manufacturing methods.

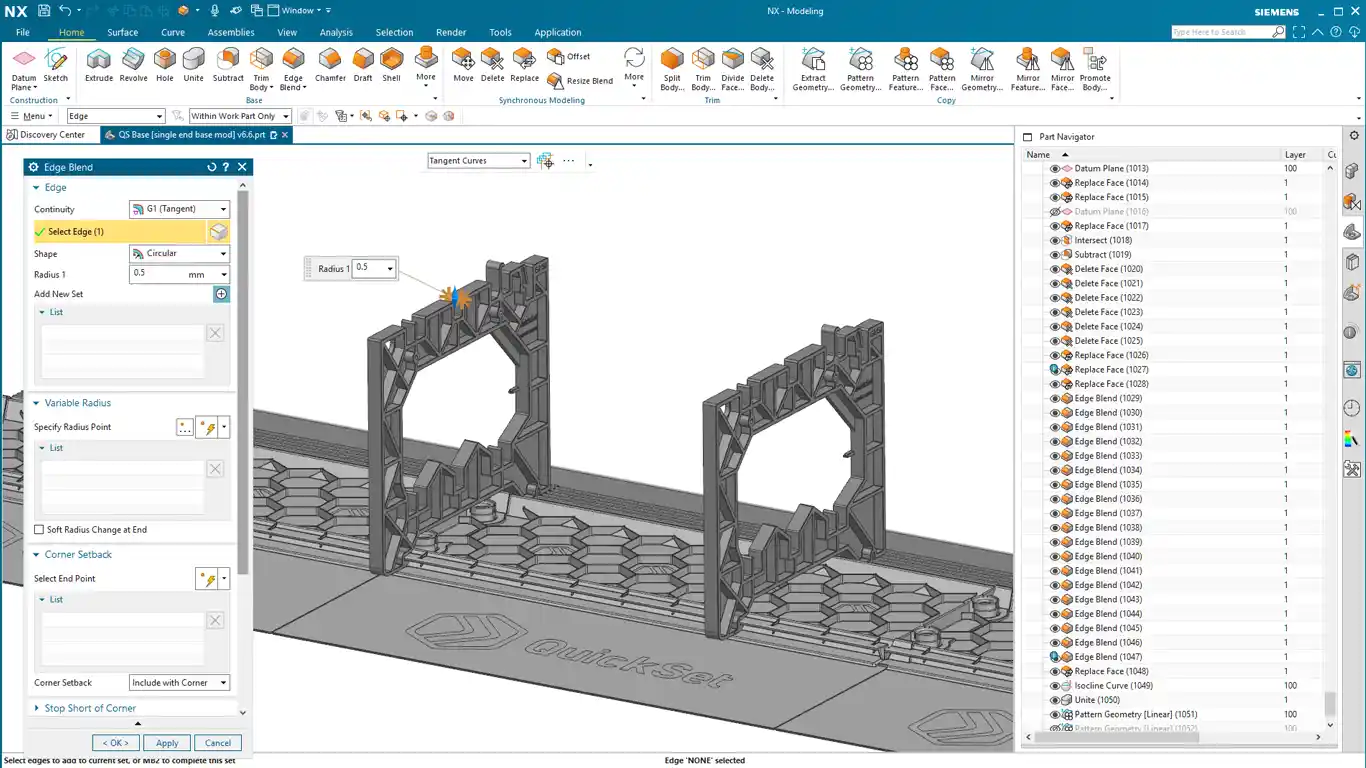

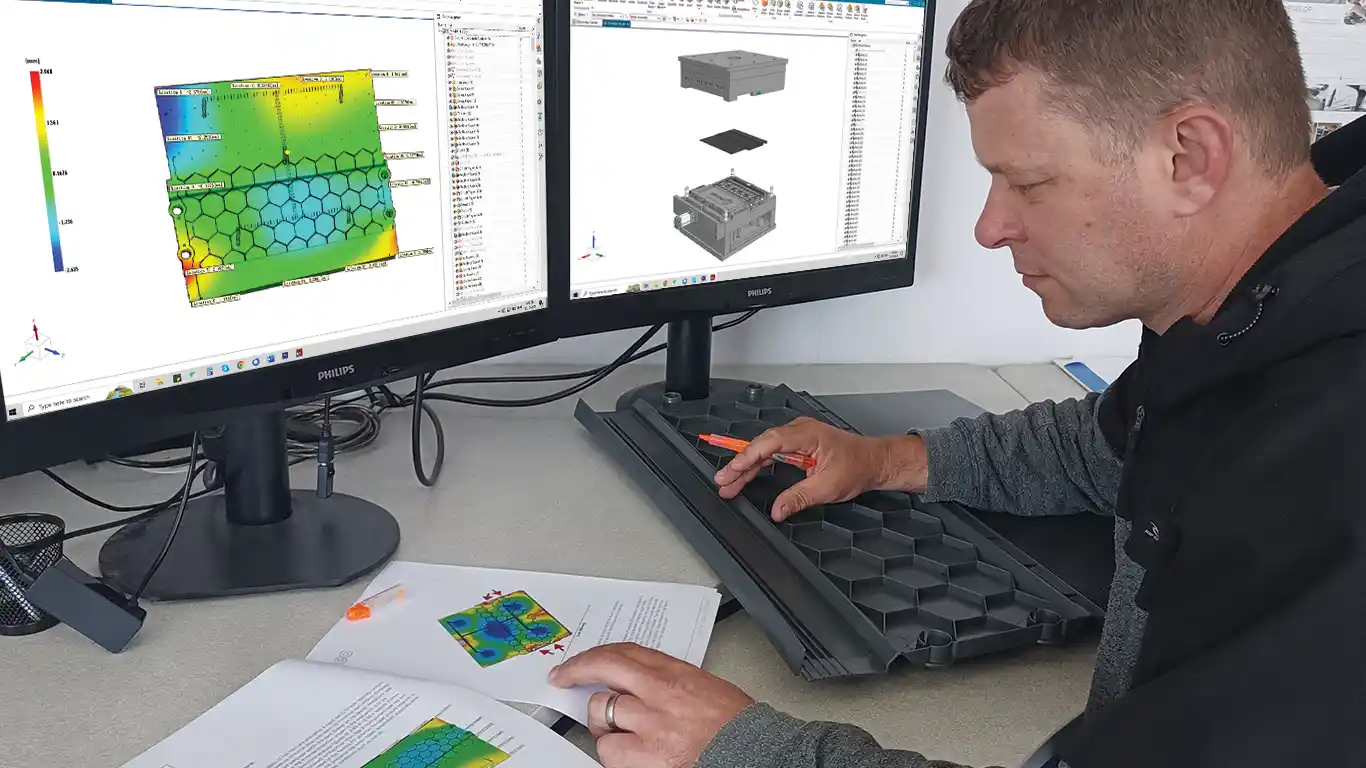

Idea’s expertise in polymers and plastic injection moulding processes was instrumental in identifying which components could be adapted and which required redesign. Leveraging Design for Manufacture (DFM) techniques and Finite Element Analysis (FEA) for strength and load simulations, Idea’s team developed precise 3D CAD assembly models, refining each component for mass production. To ensure success, the team conducted mould flow simulations and analysed the performance of large (600 x 500 mm), thin-walled (2.0 mm) sections, minimising risk and optimising the efficiency of injection mould tooling. Collaborating closely with QuickSet’s toolmaker throughout the process, Idea’s engineers ensured the final design was true to original intent, tested, and fit for purpose.